All About Air Management Systems

Air Management Systems (AMS) are crucial components in various industries, from aviation to automotive and manufacturing. These systems ensure optimal air flow and quality, enhancing performance, safety, and comfort. In this blog, we’ll explore the fundamental aspects of AMS, including their components, types, and applications across different sectors, along with recent innovations and future trends.

What is an ‘Air Management System’?

Air Management Systems are engineered solutions designed to control and optimize the flow and quality of air in various applications. Whether it’s maintaining cabin pressure in aircraft, managing ride comfort in vehicles, or ensuring efficiency in industrial processes, AMS plays a pivotal role.

An industrial air management system is a comprehensive solution designed to oversee and regulate air quality, ventilation, and emissions within manufacturing environments. It is crucial for optimizing indoor conditions to enhance worker well-being, ensure regulatory compliance, and improve operational efficiency. By leveraging real-time monitoring and automation, the system maintains a safe and healthy atmosphere while minimizing environmental impact.

This advanced system can detect a range of factors, including pollutants such as dust and chemicals, as well as temperature and humidity levels. It also assesses ventilation effectiveness and equipment performance. Through its sophisticated algorithms, the air management system enables real-time monitoring to ensure optimal air quality and suitability for employees. Additionally, it identifies potential issues that could affect productivity and safety, allowing for proactive interventions.

This blog will provide a comprehensive overview of AMS, focusing on their components, types, and applications, along with recent advancements in the field.

Key Components of Air Management Systems

Sensors: These devices measure various parameters such as pressure, temperature, and humidity. Sensors are essential for providing real-time data to the system, enabling precise control of air flow and quality.

Controllers: Controllers process data from sensors and make decisions based on predefined algorithms or user inputs. They regulate the operation of other components to maintain optimal air conditions.

Valves: Valves control the flow of air through the system. They can be either manual or automatic, and they play a crucial role in adjusting the volume and direction of air flow.

Compressors: Compressors increase the pressure of air, making it suitable for various applications. In AMS, compressors ensure that sufficient air pressure is available for proper system operation.

How These Components Work Together to Manage Air Flow and Quality

In a typical AMS, sensors continuously monitor the air conditions and send data to the controller. The controller analyzes this data and commands the valves to adjust air flow accordingly. If the system requires increased air pressure, the compressor is activated to ensure adequate supply. This coordinated action ensures that air flow and quality are maintained at optimal levels.

Types of Air Management Systems

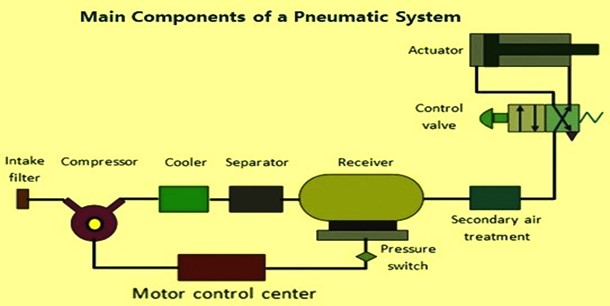

Pneumatic Systems

The pneumatic system has been pivotal in the mechanical field and is increasingly utilized in the development of industrial automation solutions. While similar to hydraulic systems, pneumatic systems rely on compressed air rather than hydraulic fluid. The term ‘Pneuma’ refers to air, and thus Pneumatics pertains to the use of compressed air to accomplish specific tasks. Pneumatic AMS use compressed air to operate and are common in industries where high-speed and high-force applications are required, such as manufacturing and automotive.

Applications: Used in automation systems, air brakes, and air suspension systems.

Electric Systems

Electric AMS use electric motors and actuators to control air flow. They offer precise control and can be more energy-efficient compared to pneumatic systems. Electric systems are prevalent in applications requiring fine-tuned adjustments.

Applications: Common in aviation for cabin pressure control and in vehicles for advanced air suspension systems.

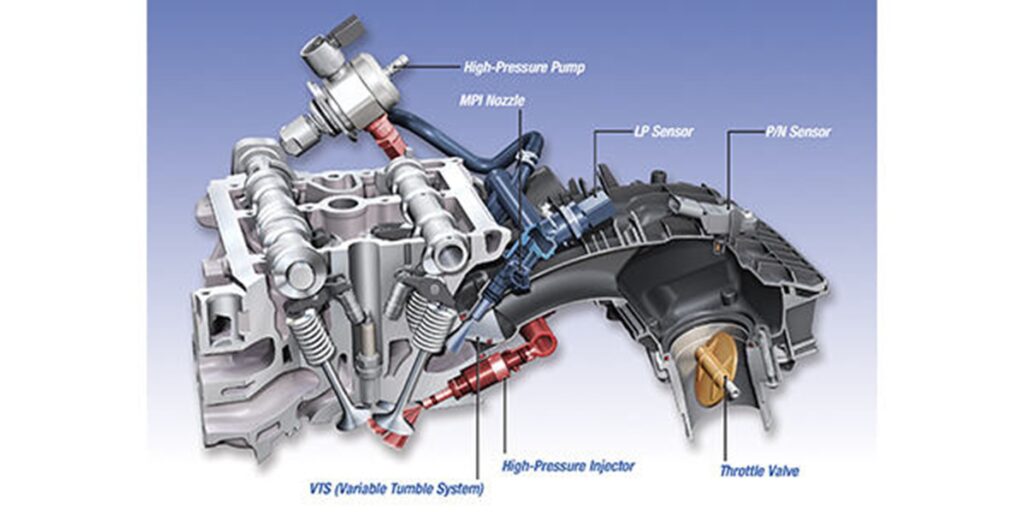

Hybrid Systems

Hybrid AMS combine both pneumatic and electric technologies. They aim to leverage the advantages of both systems, providing enhanced performance and flexibility. In automotive the technology is designed to improve vehicle efficiency by optimizing the management of air and fuel within an engine. While the specific features can vary by manufacturer, the general concept involves combining conventional internal combustion engines with advanced air management techniques. In some cases, HAMS might be integrated with hybrid electric vehicle systems, using an electric motor to assist with propulsion and reduce reliance on the internal combustion engine alone. The system uses advanced electronic controls to continuously monitor and adjust various parameters to optimize engine performance and efficiency.

Applications: Used in advanced manufacturing processes and high-performance vehicles.

Applications in Aviation

Cabin Temperature Control and Air Quality

Planes are the quickest and most comfortable way to travel, and they definitely offer an exhilarating way to reach your destination. Although a two-hour flight can be enjoyable, longer journeys often lead to back pain, fatigue, swollen limbs, and a strong desire to stretch once back on solid ground. The key to surviving these lengthy and tiring flights for both passengers and crew is the air management systems. In aircraft, AMS are vital for maintaining cabin temperature and air quality. They are an essential component of the Environmental Control System (ECS), which manages air supply, cabin pressurization, and thermal regulation within the aircraft. Beyond these functions, the ECS also oversees smoke detection, fire suppression, and the cooling of avionics components, making it a crucial element of the aircraft’s overall air and temperature management system.

Systems such as Honeywell’s EnviroSystems and Collins Aerospace’s Air Management Systems ensure that passengers experience a comfortable and safe environment. These systems manage temperature, humidity, and cabin pressure, enhancing overall flight comfort and safety.

Benefits for Passenger Comfort and Safety

By regulating cabin temperature and air quality, Air Management Systems (AMS) significantly enhance passenger comfort, helping to reduce fatigue and improve the overall flight experience. These systems meticulously control the cabin environment to maintain an optimal temperature and humidity level, which is vital for preventing discomfort and ensuring a pleasant journey. Furthermore, AMS plays a critical role in maintaining clean and well-oxygenated air throughout the flight. This is especially important on long-haul flights, where passengers are exposed to the confined space of the aircraft for extended periods. The ability to deliver fresh, high-quality air helps mitigate the effects of prolonged travel, contributing to a more enjoyable and less exhausting flight experience. Additionally, AMS supports the health and well-being of passengers and crew by preventing the buildup of contaminants and ensuring a consistent supply of breathable air.

Applications in Automotive

Air Suspension and Vehicle Dynamics

In the automotive industry, Air Management Systems (AMS) are increasingly critical, particularly in air suspension systems. These systems utilize compressed air to adjust a vehicle’s ride height dynamically, offering a range of benefits over traditional suspension systems. Here’s an in-depth exploration of how AMS is transforming the automotive sector, along with future trends that promise to enhance their performance and integration.

Current Role of AMS in Automotive Air Suspension Systems

Air suspension systems are a notable application of AMS in the automotive industry. By leveraging compressed air to adjust the ride height of a vehicle, these systems offer several advantages:

Superior Ride Comfort: Air suspension systems provide a smoother and more adaptable ride compared to traditional coil or leaf spring suspensions. The ability to adjust the suspension height and stiffness in real-time ensures that the vehicle can respond to different road conditions and loads, significantly enhancing passenger comfort.

Improved Handling: By adjusting the ride height and maintaining optimal tire contact with the road, air suspension systems improve vehicle handling and stability. This dynamic adjustment helps in reducing body roll during cornering and provides better control in various driving conditions.

Load-Leveling Capability: Air suspension systems automatically adjust the ride height to compensate for changes in load, ensuring that the vehicle remains level regardless of the weight it is carrying. This is particularly useful for vehicles that frequently haul heavy loads or tow trailers.

Customizable Driving Experience: Many air suspension systems let drivers adjust the ride height and firmness settings to their liking, providing a customizable driving experience. This flexibility can enhance both performance and comfort based on individual driving needs.

Advantages: Enhanced ride comfort, better handling, and adjustable ride height for varying loads.

Key Players

Companies like AccuAir Suspension are at the forefront of automotive AMS, providing innovative solutions that improve vehicle performance and driver experience.

Industrial Applications

Manufacturing and Automation

In industrial settings, AMS are used in manufacturing and automation processes to ensure efficient operation. Pneumatic systems are used for powering tools and controlling machinery.

Benefits for Efficiency and Safety

AMS improve efficiency by automating processes and enhancing the precision of manufacturing operations. They also contribute to safety by ensuring that machinery operates within safe parameters.

Examples

SMC Corporation is a leading provider of industrial AMS, offering solutions that streamline manufacturing processes and improve safety.

Latest Innovations and Trends

Technological Advancements

Recent advancements in AMS include the integration of IoT and smart technologies. These innovations allow for remote monitoring and control, predictive maintenance, and real-time data analysis.

Integration with IoT and Smart Technologies

IoT-enabled AMS can communicate with other systems and devices, providing more comprehensive control and monitoring. This integration helps in optimizing system performance and reducing downtime.

Future Trends

The future of AMS will likely see further integration with smart technologies and increased use of AI for predictive maintenance and system optimization. Advances in materials and manufacturing techniques will also contribute to more efficient and reliable systems.

Here’s a look at some of the key future trends in air management systems:

1. Increased Integration of Artificial Intelligence (AI)

AI is set to revolutionize air management systems by enhancing predictive maintenance, optimizing air flow, and improving overall system efficiency. AI algorithms can analyze vast amounts of data from sensors to predict potential failures or inefficiencies, enabling preemptive measures and reducing downtime. AI can also optimize air flow and temperature management in real-time, leading to more efficient operation.

2. Advanced Sensor Technologies

The future will see the integration of more sophisticated sensors within air management systems. These sensors will offer higher precision and reliability in monitoring parameters such as temperature, pressure, and humidity. Enhanced sensors will enable better real-time adjustments and contribute to the development of autonomous or semi-autonomous air management systems.

3. Sustainability and Energy Efficiency

With growing environmental concerns, there will be a strong emphasis on developing air management systems that are more energy-efficient and sustainable. This includes advancements in materials that reduce energy consumption, as well as systems designed to minimize environmental impact. For instance, incorporating energy recovery systems or utilizing renewable energy sources will become more prevalent.

4. Integration with IoT

The Internet of Things (IoT) will play a significant role in the evolution of air management systems. IoT connectivity will enable real-time data sharing and remote monitoring, facilitating better decision-making and system management. This connectivity will also allow for seamless integration with other systems, leading to more coordinated and efficient air management.

5. Enhanced Air Quality Management

Future air management systems will place a greater focus on improving air quality, particularly in confined or enclosed spaces. Advanced filtration systems, including those using nanotechnology or electrostatic filters, will become more common. Additionally, air purification technologies will be integrated to ensure cleaner and healthier air, addressing growing concerns about air pollution and indoor air quality.

6. Adaptive and Self-Learning Systems

Adaptive systems that can learn and adjust based on changing conditions will become more prevalent. These systems will use machine learning algorithms to continuously improve their performance based on historical data and real-time inputs. This self-learning capability will enhance the efficiency and reliability of air management systems.

7. Modular and Scalable Designs

Future air management systems will increasingly feature modular and scalable designs. Modular systems allow for easier upgrades and maintenance, while scalable designs ensure that the systems can be adapted to varying sizes and requirements. This flexibility will be particularly important in rapidly changing industries such as aerospace and automotive.

8. Enhanced Safety Features

Safety will remain a top priority, with future systems incorporating advanced safety features such as automated emergency responses and improved fail-safe mechanisms. Enhanced safety protocols and real-time monitoring will ensure that air management systems can promptly address and mitigate potential hazards.

9. Advanced Computational Fluid Dynamics (CFD)

Computational fluid dynamics will continue to advance, providing more detailed and accurate simulations of air flow and thermal dynamics. This will lead to better design and optimization of air management systems, improving their performance and efficiency.

10. Cybersecurity Measures

As air management systems become more interconnected and reliant on digital technologies, cybersecurity will become increasingly important. Future systems will incorporate robust security measures to protect against cyber threats and ensure the integrity of critical data and operations.

Pros and Cons of Air Management Systems:

- Pros of Air Management Systems

Enhanced Comfort and Safety

Aviation: In aircraft, AMS ensures optimal cabin pressure, temperature, and air quality, significantly improving passenger comfort and safety.

Automotive: In vehicles, AMS contributes to improved ride comfort through air suspension systems and maintains optimal cabin conditions.

Industrial: In manufacturing, AMS helps maintain a safe and comfortable work environment by controlling air quality and ventilation.

Regulatory Compliance

AMS help organizations comply with stringent regulatory standards related to air quality, emissions, and safety. This is crucial in industries like aviation and manufacturing where regulations are rigorous.

Operational Efficiency

Energy Management: Advanced AMS optimize energy use by managing air flow and pressure, which can lead to cost savings on energy and reduced operational costs.

Predictive Maintenance: Integration with smart technologies allows for real-time monitoring and predictive maintenance, minimizing downtime and extending the lifespan of equipment.

Improved Air Quality

AMS effectively filters and manages contaminants such as dust, chemicals, and pollutants, leading to cleaner and healthier air. This is particularly important in industrial environments and aircraft cabins.

Advanced Technology Integration

Modern AMS often integrate with IoT and AI technologies, providing advanced features such as real-time data analysis, remote monitoring, and automated adjustments. This enhances system performance and user control.

Customization and Flexibility

AMS can be customized to meet specific needs of different applications, providing flexibility in various environments such as commercial aviation, automotive, and industrial settings.

- Cons of Air Management Systems

High Initial Costs

The installation and integration of advanced AMS can be expensive. This includes the cost of the system itself, as well as installation, training, and potential system upgrades.

Complexity and Maintenance

AMS can be complex, requiring specialized knowledge for installation, operation, and maintenance. This complexity can lead to higher costs for training and maintenance, as well as potential operational challenges if not properly managed.

Technology Dependence

The reliance on advanced technology means that any malfunction or failure in the system can impact air quality and system performance. Continuous monitoring and maintenance are essential to prevent issues.

Potential for Over-Specification

In some cases, AMS may be over-specified for the needs of the application, leading to unnecessary features and costs. Careful planning and needs assessment are required to ensure that the system is appropriately scaled.

Integration Challenges

Integrating AMS with existing systems and infrastructure can be challenging. There may be compatibility issues, requiring more time and resources to resolve.

Energy Consumption

While AMS can optimize energy use, they can also consume significant amounts of energy, particularly in systems that involve compressed air or extensive ventilation. This can offset some of the cost savings associated with energy management.

Dependence on Real-Time Data

The effectiveness of AMS often relies on accurate and real-time data. Any discrepancies or errors in data collection can lead to incorrect system adjustments and potentially affect performance.

According to TechSci Research report “Aircraft Air Management Systems Market – Global Industry Size, Share, Trends Opportunity, and Forecast, Segmented By System Type (Thermal Management System, Engine Bleed Air System, Oxygen System, Fuel Tank Inert System, Cabin Pressure Control System, and Ice Protection System), By Aircraft Type (Commercial Aircraft, Business Aircraft, Defense Aircraft, and Others), By Region, Competition, 2019-2029F,” the Global Aircraft Air Management Systems Market size reached USD 5.37 billion in 2023 and is expected to grow with a CAGR of 7.44% in the forecast period. The market is experiencing significant growth, driven by several key factors. These systems are crucial for maintaining cabin comfort, safety, and operational efficiency in modern aircraft.

The following factors are contributing to the expansion of this market.

1.Increasing Air Travel Demand

The rising demand for air travel, fueled by growing economies and expanding middle-class populations, is a primary driver of AMS market growth. As airlines add new aircraft to their fleets and upgrade existing ones, the need for advanced air management systems to enhance passenger comfort and safety becomes more pronounced.

2. Technological Advancements

Advancements in technology are continuously improving the performance and efficiency of AMS. Innovations such as real-time monitoring, advanced sensors, and integrated control systems enhance the accuracy and reliability of air management. These technological improvements are encouraging airlines and aircraft manufacturers to adopt the latest AMS solutions.

3. Focus on Passenger Comfort

Airlines are placing greater emphasis on passenger comfort as a key competitive differentiator. Contemporary Aircraft Management Systems (AMS) are engineered to enhance the flying experience by optimizing cabin temperature, humidity, and air quality. This commitment to improving passenger experience is accelerating the adoption of advanced air management technologies.

4. Regulatory Requirements and Standards

Stringent regulatory requirements and safety standards imposed by aviation authorities worldwide are pushing the industry towards more sophisticated AMS. Compliance with regulations related to cabin pressure, air quality, and safety standards necessitates the use of advanced air management solutions.

5. Energy Efficiency and Sustainability

There is a growing emphasis on energy efficiency and environmental sustainability in the aviation sector. Advanced AMS contribute to these goals by optimizing energy use and reducing the environmental impact of aircraft operations. This aligns with the broader industry trend towards greener and more sustainable aviation practices.

6. Increase in Aircraft Fleet Modernization

Aircraft fleet modernization programs are another significant driver of the AMS market. As airlines and operators replace older aircraft with newer models, they are increasingly incorporating advanced AMS to enhance operational efficiency and meet modern performance standards.

7. Growth of the Aerospace Industry

The overall growth of the aerospace industry, driven by technological advancements and increasing defense spending, supports the expansion of the AMS market. Both commercial and military aviation sectors are investing in new aircraft and upgrading existing ones, thereby driving demand for advanced air management solutions.

8. Integration with Smart Technologies

The integration of AMS with smart technologies, including Internet of Things (IoT) and artificial intelligence (AI), is enhancing system capabilities. These smart systems offer predictive maintenance, real-time data analytics, and improved operational control, further driving market growth.

9. Emergence of New Market Players

The entry of new players into the Air Management Systems (AMS) market is significantly influencing the landscape of this industry, driving innovation, enhancing competition, and contributing to its growth and evolution. As new companies bring fresh perspectives and advanced technologies, they are reshaping traditional approaches and pushing the boundaries of what is possible in air management.

10. Enhanced Focus on Safety and Reliability

Improving safety and reliability is a continual focus in aviation. Advanced AMS help in monitoring and managing cabin pressure, air quality, and other critical factors that directly impact the safety and operational reliability of aircraft. This focus on enhanced safety features drives the adoption of advanced systems.

In summary, the global aircraft air management systems market is driven by a combination of increasing air travel demand, technological advancements, regulatory requirements, and a growing emphasis on passenger comfort and sustainability. As these factors continue to evolve, the market for AMS is expected to see sustained growth and innovation.

Conclusion:

Air Management Systems are integral to a wide range of applications, from ensuring passenger comfort in aviation to enhancing vehicle performance and industrial efficiency. Their importance stems from their ability to regulate air pressure, temperature, and flow, thereby influencing the operational effectiveness and safety of various applications. Understanding their components, types, and applications helps in appreciating their significance across various sectors. As technology continues to evolve, AMS will likely see further innovations, enhancing their capabilities and applications even further.